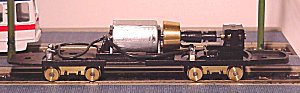

Bowser was right on most counts, as long as you were using the unit powered two-rail and most modelers do. Those of us (known on some circles as “ the crazies”) who erect complicated overhead wire and run trolleys from it soon found out the advantages of flywheels. Using overhead wire forces reliance on a single electrical contact from overhead wire. This wire tends to get dirty especially on traction modules that are transported to different places for various appearances. We also sought to use the Bowser trolley mechanisms in other cars, especially Pacific Electric Interurbans with truck wheelbases very close to that of the Bowser mechanism wheelbase. Four new sideframes were manufactured in pewter to date. Sideframes are available currently in pewter for the St. Louis 23B, 61A, Brill 27MCB3X and Baldwin 78-30 trucks, and more are planned. As the modules of the Southern California Traction club aged, the problems of dirty track and wire escalated and we soon found ourselves noticing that the cars with flywheels were easier to get running on the displays. We then turned to master mechanic, Joe Delia of Proto Power West/A-line, for input and he delivered so quickly that it was amazing. He produced a retrofit kit that will be shortly on the market. It contains four parts and a flywheel and can be placed on any Bowser 99 mechanism in less than ten minutes. For the record, the first photo below is of the Bowser 99 PCC mechanism with floor. The second photo shows another Bowser 99 PCC mechanism with the new A-line flywheel kit installed. Both chassis are being displayed on one of Transquip new HO scale trolley display modules. They will be a Trolleyville vendor very soon so watch for their page.   There are only a few small tools required for the installation of the A-line flywheel kit and specific instructions come with the kit and are the subject of a lesson in the schoolhouse Trolleyville. There are instructions also in the kit. Although not required, a Dremel tool with cutting disks can be useful, otherwise only a small screwdriver, flat file and a razor saw are needed. It should be mentioned that due to the eight wheel electrical pick-up, you might not notice the performance improvement due to the flywheel until you come to some dirty track. Those hardy souls, like the writer, who love to operate from powered overhead wires, will notice the performance improvement much sooner. Custom Traxx obtained a completed chassis and three R&D units on Saturday, February 10 and installed two of them in Bowser PCC cars that evening. Both cars ran during the Anaheim Great American Train Show on Sunday, February 11th . Two days later, the third unit was installed in Montreal & Southern Counties #621, which was the first brass car so configured. All three cars ran during the Sahuaro Central “Everything Railroad” Winter Swap Meet on Saturday, February 17th. Evaluations will continue with more cars, but the first three run fine. The universal joints supplied by A-line in the flywheel kit have a little more freedom then the original ones supplied by Bowser so the “buzzing” sound emitted on sharp curves is eliminated. A-line is working on other improvements for the Bowser drives so keep visiting Trolleyville. New items will be announced and evaluated in the Trolleyville Times as soon as the products are on the market. |

[an error occurred while processing this directive]

Copyright 2001 GLA Computer Services